The energy industry is constantly evolving, with new advancements driving efficiency, sustainability, and productivity. In recent years, one technology that has taken center stage is the use of pallet handling robots. These cutting-edge machines are revolutionizing the way the energy industry handles pallets, delivering unrivaled efficiency and precision in a sector that demands reliability and optimization.

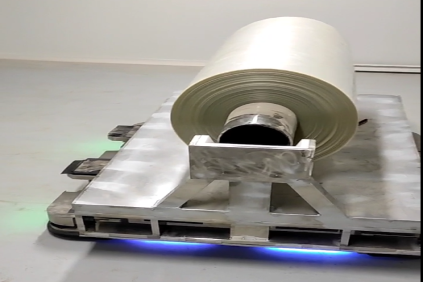

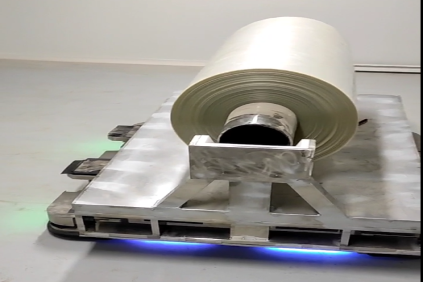

Pallet handling robots are specifically designed to streamline the movement, storage, and transport of pallets within the energy industry. From renewable energy projects and power generation plants to oil and gas facilities, these robots have found their way into every corner of the sector. Their advanced capabilities and features make them indispensable for companies seeking to improve their operations.

One of the key advantages of pallet handling robots is their ability to automate and optimize various processes. These robots can efficiently load and unload pallets, arrange them in storage areas, and transport them to different locations within a facility. Their precise movements, guided by advanced sensors and software, allow them to navigate complex environments, avoiding obstacles and ensuring a seamless flow of pallets with minimal human intervention.

The introduction of pallet handling robots has resulted in significant improvements in productivity and safety. These machines can work tirelessly, 24/7, with minimal downtime or breaks. They handle heavy loads effortlessly, reducing the risk of injury and strain on human workers. By automating mundane and repetitive tasks, human workers can be freed up to focus on more complex and value-added activities, fostering greater productivity and job satisfaction.

Moreover, pallet handling robots deliver exceptional accuracy and consistency. Their advanced programming and sensors enable precise positioning and movement of pallets, minimizing errors and reducing the chances of damaged products or equipment. This level of precision ensures that pallets are efficiently stored, sorted, and retrieved, contributing to streamlined operations and efficient supply chain management.

In addition to their operational benefits, pallet handling robots also enhance the overall sustainability of the energy industry. These robots optimize energy usage by operating with greater efficiency and reducing wasteful movements. Their ability to stack pallets higher and use available storage space more effectively results in minimal wastage of valuable floor space. By reducing the carbon footprint associated with pallet movement, these robots actively contribute to a greener and more sustainable energy industry.

Another notable advantage of pallet handling robots is their adaptability and scalability. These machines can be programmed to handle various pallet sizes, weights, and shapes, making them suitable for a wide range of applications within the energy industry. Additionally, as operational needs evolve, pallet handling robot systems can be expanded or reconfigured to accommodate changing requirements, providing businesses with flexibility and future-proofing their operations.

In conclusion, the introduction of pallet handling robots in the energy industry has been a game-changer. These machines bring unmatched efficiency, precision, and productivity to pallet movement, storage, and transport. With their automation capabilities, accuracy, and scalability, these robots not only streamline operations but also contribute to sustainability efforts. As the energy industry continues to embrace technological advancements, pallet handling robots lead the way in revolutionizing the efficiency and effectiveness of pallet management.